Events

Chemtrix & our agents regularly visit conferences & exhibitions where leading Academics & Industrialists showcase the latest developments in Flow Chemistry. Exhibitions provide an opportunity to see our equipment, network & discuss potential applications. Want to take the first steps, or learn more about Flow Chemistry? We invite you to visit us at an upcoming event!

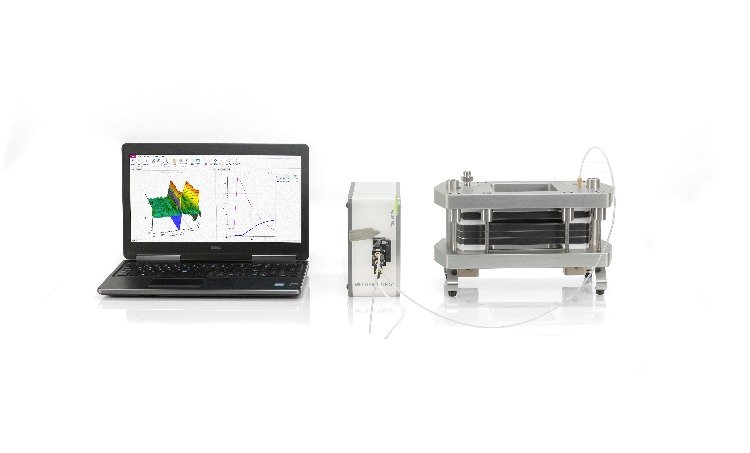

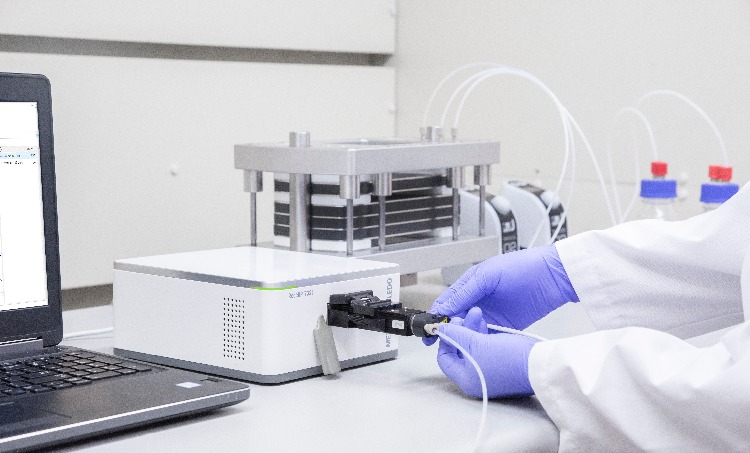

Continuous Flow Optimisation & Control with Mettler Toledo

October saw us join Mettler-Toledo International Inc for their live webinar series on the role of PAT in ‘Continuous Flow Optimisation & Control’. Together with speakers from Nalas Engineering Services Inc., Snapdragon Chemistry & APC Ltd. a range of topics were covered from the use of PAT in primary processing through to controlled crystallisation.

Why Continuous Flow?

The advantages of changing from batch to flow are widely publicised to include increases in safety, process efficiency & product consistency; however, the reasons for a Company to change are varied, often depending on the sector, process type of interest, scale of operation & location of activities. As a result of this variety in application space & the emerging nature of the technique, close partnering between vendors & end users is needed to ensure correct tool selection & implementation strategy is employed from the outset.

Role of Process Analytical Technology (PAT)?

Appropriate analytical evaluation is key to designing an efficient continuous process. In these presentations examples were selected to demonstrate the translation of existing processes from batch to flow, showing how PAT has been used to develop production protocols that; enable manufacturing to be brought back ‘in-house’ & production quantities to be accessed that were not feasible using conventional batch technology.

Examples of PAT include;

- FTIR

- Raman

- DESI-MS

- FBRM

Interested to learn more? Visit our Download page to access a copy of our presentation or Listen Again.