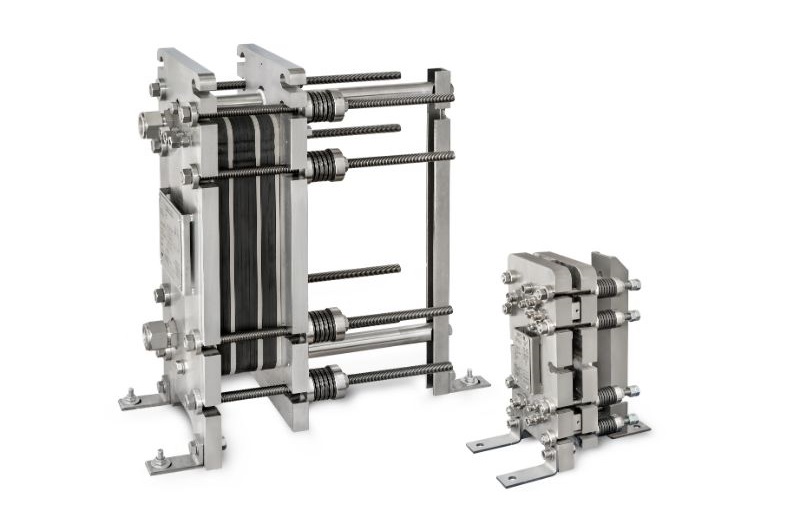

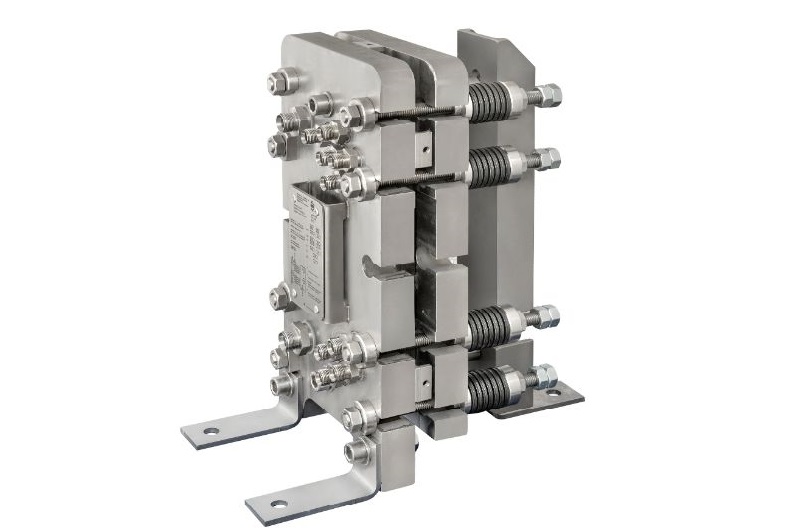

Plantrix® MR260

Plantrix MR260 is a modular ceramic Flow Reactor for process development, pilot & full-scale production. With integrated heat exchange, Plantrix gives optimal control for challenging chemistries & process intensification at scale.

Plantrix® MR260

Plantrix MR260 is a modular, ceramic Flow Reactor for process development, pilot & full-scale production. Fabricated from diffusion bonded 3MTM SiC (silicon carbide), with integrated heat exchange, Plantrix modules give unrivalled chemical compatibility & process control for challenging chemical applications at scale.

Employing standard compression tube fittings, Plantrix can be used with existing pumps & thermostats, or supplied as total systems on request.

Examples of User applications:

- Fast, strongly exothermic reactions

- Reactions with aggressive media / unstable intermediates

- Material supply under GMP conditions

- Processes include nitrations, cyanations, lithiations, diazotisations & halogenations

Interested to see how other Customers use our systems? See our Reference Cases

Want to know more? Use the buttons below to make your request!

SPECIFICATIONS

- Flow rate: 17-600 ml/min (up to 36 kg/h)

- Reactor volume: 2.9 up to 170 ml

- Wetted materials: SiC, PTFE & FFKM (tube fitting Ti or HC)

- Dimensions: 206 (W) x 435 (D) x 720 mm (H)

3M™ SiC is a registered trademark of 3M Germany

Request Technical Information

Please fill out this form & you will receive a download link by e-mail

Request Quote

Please fill out this form to request your quote

_1587386847.jpg)