News

Read the latest news, case studies & event reports from our Flow Community! Want to stay up to date? Sign-up for our newsletter & a few times per year we will e-mail you interesting articles, developments, up-coming event info!

Controlling Innovation to Deliver High Value-Low Volume, Flexible, Continuous Manufacturing

31 March 2020

Chemtrix is delighted to be collaborating with Perceptive Engineering Singapore & a multinational pharmaceutical company in Singapore to deliver a collaborative solution for the production of high value-low volume chemical/pharmaceutical production through small scale flexible continuous manufacturing.

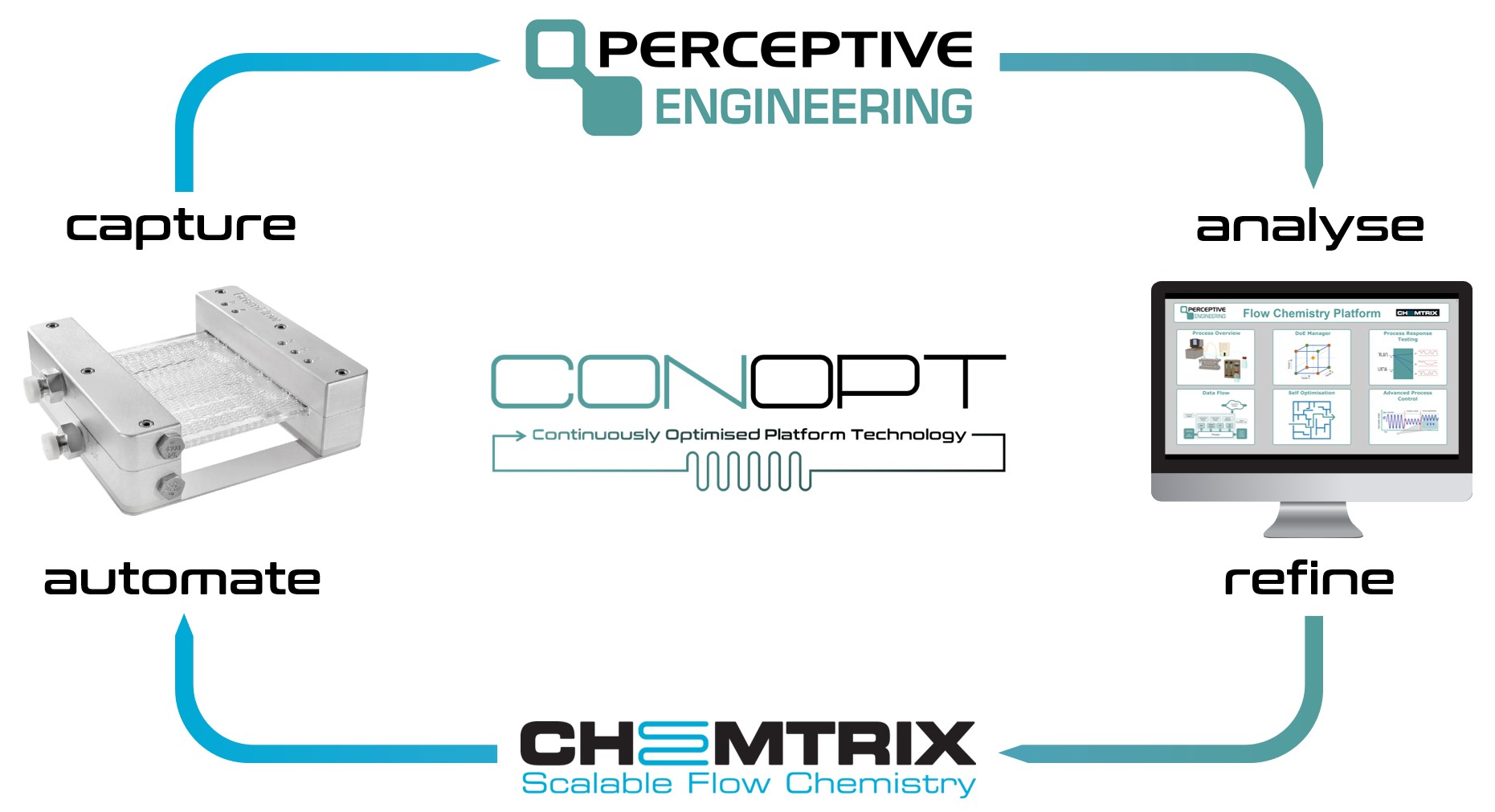

Following the successful GlobalStars award from the Eureka network, for the CONtinuously Optimal Platform Technology (CONOPT) project, Perceptive Engineering Singapore will bring together flow reactor hardware from Chemtrix, process development & advanced process control/analytics to develop a powerful AI platform (PerceptRON), & a Benefits Quantification Methodology (BQM) decision support tool. This integrated system will minimise the risks associated with transitioning from batch to continuous processing within the pharmaceutical sector.

The BQM will put a value on the potential advantages that can be derived by switching from batch to the more flexible continuous manufacturing systems, overcoming a key barrier in the development of an investment case for new technology over established assets.

CONtinuously Optimal Platform Technology (CONOPT) project - Controlling Innovation to Deliver High Value-Low Volume, Flexible, Continuous Manufacturing.

David Lovett, CEO of Perceptive Engineering Singapore commented:

“Through this collaborative project we are expanding the Perceptive software platform, incorporating the latest AI techniques to simplify the setup, operation & performance of Chemtrix’s innovative flow reactors. With guidance from our pharmaceutical network, & specifically a partnership with a Pharmaceutical MNC in Singapore, we are developing the next generation operating platform & productivity tools for continuous flow chemistry manufacturing. Through the integration of PAT, Modern Experimental Designs, & precision model-based control, all embedded in a containerised platform, the system should hugely simplify the management of flow reactors. Adding a cloud connection & a business case assessment method for converting from batch to continuous processing, we believe we are delivering a comprehensive solution. We are excited & privileged to be working closely with Chemtrix & their global network of experts. The 20-month programme, now underway, will release an on-premise product in 2020, followed by the edge/cloud-based system in 2021.”

Dr. Charlotte Wiles, CEO of Chemtrix BV commented:

“Continuous manufacturing (CM or Flow Chemistry) is gaining global importance not only as a research tool but also as a production technique. Whilst benefits such as increased process safety, reduced energy consumption & reduced waste generation are widely noted, gaps remain in clearly defining a business case when assessing whether to go ‘batch to flow’ & subsequently in developing appropriate control strategies for CM. We are looking forward to strengthening our collaboration with Perceptive Engineering to develop this comprehensive hardware & software solution – culminating in a demonstrator with a leading pharmaceutical company in Singapore.”

Through the GlobalStars CONOPT project, the BQM, Optimised Experimental Design Platform & continuous flow PAT/model-based automation is being developed to increase productivity in advanced manufacturing companies focussed on complex formulated products such as pharmaceuticals, chemicals & personal healthcare products.

For further information contact:

Simon Mazier Danielle Raats

Perceptive Engineering Marketing Director Chemtrix Sales & Marketing Coordinator

smazier@perceptiveapc.com d.raats@chemtrix.com

+44 1925 607150 +31 46 70 22 600

About Perceptive Engineering

The company offers a unique software platform which combines off-line data analytics with development & testing of process monitoring, control & optimisation strategies, then seamlessly enables these to be implemented in a robust real-time environment. The PerceptiveAPC software suite has already been selected by multinational companies such as Pfizer, GlaxoSmithKline, Takeda, Unilever & Mondelez, to spearhead process understanding & intensification. The company has offices in UK, Singapore, USA & Ireland, & collaborates with clients & leading research institutes around the world to help develop the solutions needed for next-generation manufacturing. www.perceptiveapc.com

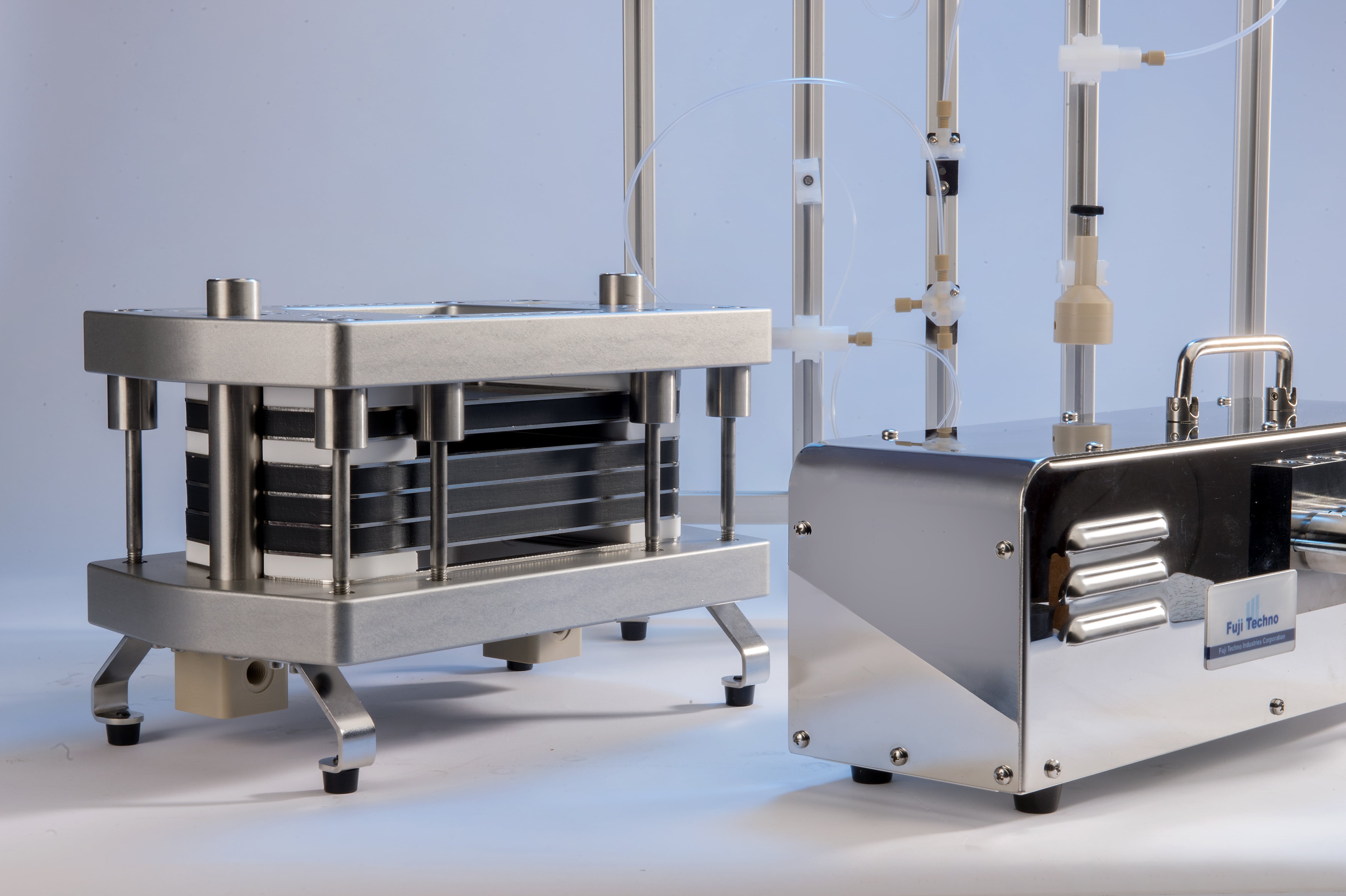

About Chemtrix

Chemtrix BV offers a scalable flow reactor portfolio that affords researchers & industrialists the tools required to harness the advantages of primary continuous manufacturing. We combine expertise in the field of mechanical engineering, chemical engineering & chemistry to help our customers to benefit from the advantages that flow chemistry brings. Our expertise enables us to offer scalable & flexible flow chemistry solutions, focussing on delivering our Customers higher profits by accessing new chemical possibilities via a safe & reliable scale-up from lab to production-scale. Working closely with academia & industry, we work to change the way that chemical processes are developed & implemented. Our global user base spans research institutes & government laboratories to leaders in the fine chemical, specialty & pharmaceutical industries. www.chemtrix.com